Custom Handcrafted Furniture in Lancaster PA

Furniture that lasts a lifetime

Tired of Poor Quality Furniture?

Does your furniture keep breaking, have unsightly water stains and other discrepancies? Do you play tug-a-war with your extension tables or wonder if that rickety wooden chair will actually hold you up?

Create a Lifetime of Enjoyment With Quality Furniture

Open with ease extension tables

Extend your tables with one person

n

Water resistant finish

Our stains and finishes cover all wood surfaces

n

100% Solid Hardwood

No Plywood or Particle Board

n

Personalized Design

Work with our designers to create your perfect piece of furniture

No wasted space

Our drawers fully extend so you don’t miss out on wasted space

Artistically matched beautiful natural grain

All of our wood is expertly chosen

Open with ease extension tables

Extend your tables with one person

Water resistant finish

Our stains and finishes cover all wood surfaces

100% Solid Hardwood

Personalized Design

Work with our designers to create your perfect piece of furniture

No wasted space

Our drawers fully extend so you don’t miss out on wasted space

Artistically matched beautiful natural grain

All of our wood is expertly chosen

Open with ease extension tables

Extend your tables with one person

Water resistant finish

Our stains and finishes cover all wood surfaces

100% Solid Hardwood

Personalized Design

Work with our designers to create your perfect piece of furniture

No wasted space

Our drawers fully extend so you don’t miss out on wasted space

Artistically matched beautiful natural grain

All of our wood is expertly chosen

We Understand How Frustrating Non-Quality Furniture Can Be

Our extensive experience of over 5 decades creating handcrafted pieces assures you’ll receive the highest value for your dollar.

Working with Chris on the design of our table and chairs was nothing short of perfect. So easy to work with and so accommodating, even when we changed what we wanted a couple of times. The table, chairs and bench were delivered today and are absolutely stunning. The craftsmanship is amazing and the person who made our table signed it. This will last a lifetime and we are just so happy with how unique it turned out. If you are thinking about whether to move forward with this company- DO IT! You won’t regret it. There aren’t many companies I’ve found that have such genuine caring and customer service, not to mention outstanding craftsmen.’

Judy B., Brookeville MD

Read all reviews for George’s >

Key Steps to Building Your Quality Furniture

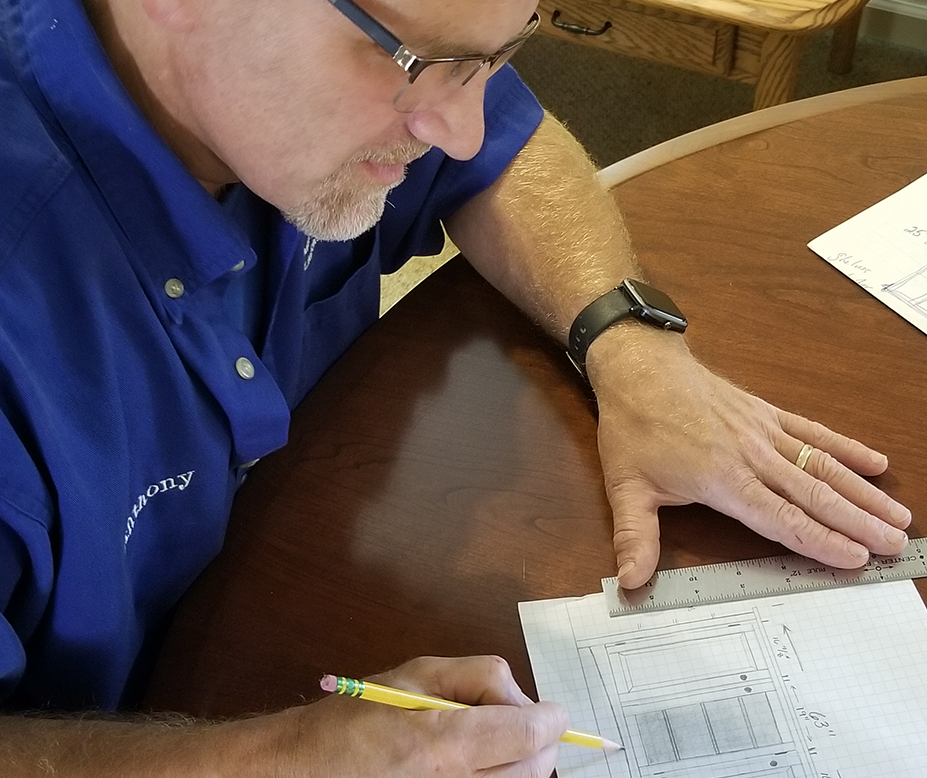

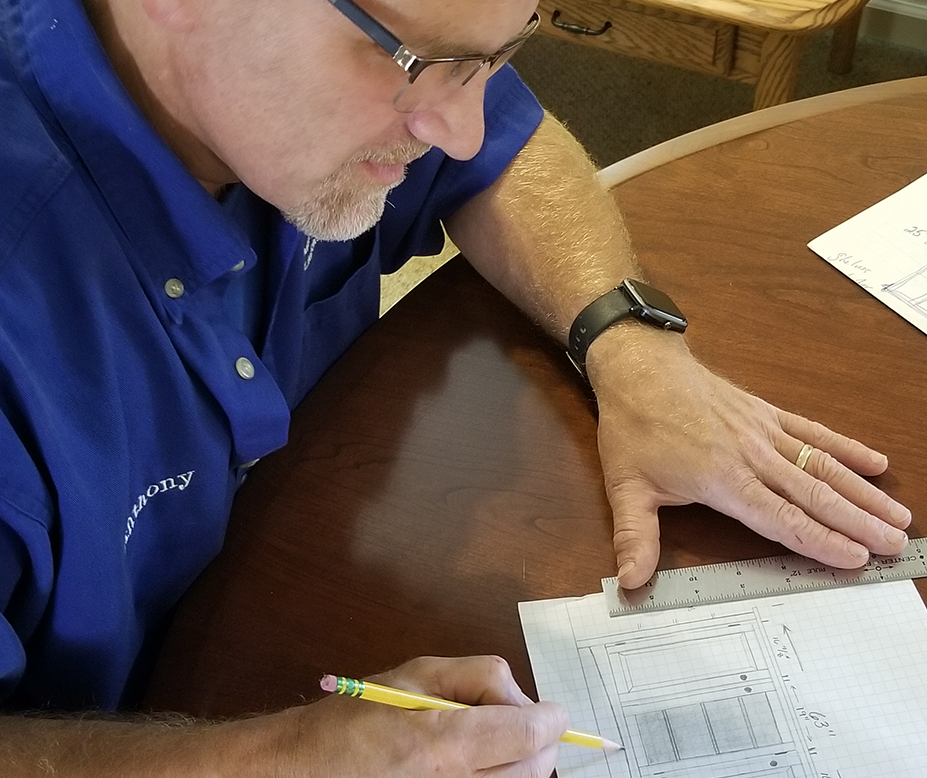

Design

Expert craftsmen listen to your ideas, discuss the options and design a plan.

Build

Our skilled craftsmen take your project and bring it to life, displaying the characteristics of solid hardwood with a signature and date as proof of authenticity.

1. Explore

Call, email or visit to discuss your project.

2. Design

Expert craftsmen listen to your ideas, discuss the options and design a plan.

3. Build

Our skilled craftsmen take your project and bring it to life, displaying the characteristics of solid hardwood with a signature and date as proof of authenticity.

The Highest Quality Furniture

At George’s Furniture, you will have confidence knowing that your purchase is the highest quality furniture for your home. High-quality furniture requires skillfully trained craftsmen, who complete a year long apprenticeship in 100% solid wood construction. Each craftsman signs and dates their finished furniture. So many stores dismiss the importance of quality which makes you incredibly frustrated. We understand your frustration, which is why we commit to constructing each piece of furniture to the utmost quality.

The next step:

1. Call us when you are ready. We’ll discuss your ideas. Whether sitting down with our expert designers or corresponding by email and phone, we can help develop the perfect piece for your living space.

2. After listening to your ideas, we will design your perfect heirloom furniture, considering the characteristics of 100% solid wood construction.

3. Upon your approval, one craftsman will bring your dream to a reality.

So call us! Meanwhile, grab our guide to 5 ways to tell your furniture is quality made, so you can stop the frustrating search for quality furniture and create a home of beautiful pieces of furniture that will exceed a lifetime.

Tired of Poor-Quality Furniture?

Download the guide on 5 ways to tell if your furniture is quality made.

Some of Our Most Cherished Creations

Non-Tip Reclining Rocker

$800-$1200

This rocking chair will never tip over and comfortable enough to sleep for hours.

Natural Grain Extension Table

$2000+

Our endless extension tables will wow you and are a customer favorite!

Non-Tip Reclining Rocker

$800-$1100

This rocking chair will never tip over and comfortable enough to sleep for hours.

Natural Grain Extension Table

$2000+

Our endless extension tables will wow you and are a customer favorite!

We Are Here To Help

Learn more about us anytime! Join our Facebook page to stay in the conversation.

Don’t forget about the quick read on 5 ways to tell your furniture is quality made!

Always feel free to call with questions or to get your project started!